Annually, millions are lost due to store stockouts

Out of Stock: A Problem for Retailers, Manufacturers, and Shoppers

Annually, millions of dollars are lost due to store Out-of-Stocks. A problem for retailers, manufacturers, and shoppers! Art Frickus and SmartSpotter measured the Out-of-Stocks of seven products at Jumbo. Read the results below.

Do you know the Out-of-Stock percentage of your running product(s)? Request a free Out-of-Stock measurement for one product of your choice.

Out-of-Stock: A Problem for Retailers, Manufacturers, and Shoppers

Do you know the feeling? You walk through your trusted supermarket with your paper or digital shopping list. Everything is going smoothly, and your shopping cart is nearly full. You're heading towards the next item on your list when you suddenly wake up. Your hand feels nothing and disappears into a black and empty void: the product isn't there! Immediately, you have a problem. What will you do? Buy a different variant of the same brand, buy a different brand, search for an alternative product, postpone the purchase, cancel the purchase altogether, or go to another (online) store? You're certainly not pleased. Especially if this happens frequently.

Store out-of-stock has received little attention in recent years. Delivery and reliability at the distribution center level have received a lot of attention (including penalty clauses that come into effect if the set standards are not met). But what about store stockouts, knowing that this is one of the biggest frustrations and reasons for shoppers to change their behavior? This, while retailers and manufacturers are facing margin pressure due to rising raw material and labor costs.

Annually, millions are lost due to store stockouts

Looking at the entire distribution chain, money is only made when the product is in the shopping cart. Research shows that millions of Dollars are lost annually due to store stock-outs. Not only in terms of immediate lost revenue but also in the long run. And the risk of losing the shopper increases. The average number of different (online) supermarkets visited by shoppers has risen to 4.9 in 2022 (Source: GfK). In other words, if the favorite product is out-of-stock, the likelihood of it being purchased elsewhere is higher.

Preventing out-of-stock is also important at the brand level. Driven in part by inflation and increasing Private Label quality, brand loyalty is decreasing.

Of course, there are exceptions to the rule, but in general, it is important for both retailers and brand suppliers to prevent out-of-stocks.

Out-of-stock rates go up to 15%, with 50% of the causes lying in-store

Aside from raw material issues, strikes, boycotts, etc., "regular" out-of-stock still occurs. Despite advanced smart distribution systems and faster, more frequent "just-in-time" store experiences.

Research shows that the average out-of-stock percentage is around 9%. In Australia measurements, this percentage sometimes goes up to 15%. Various root cause analyses reveal that the store itself is responsible for about half of these out-of-stocks. Some causes include the number of facings on the shelf, the product being in the store warehouse, restocking moments and frequency, missing price tags, and incorrect shelf placement.

Measuring is Knowledge

Awareness of stockouts begins with measuring, knowing if and to what extent they occur. Based on the outcome, it's possible to quickly calculate an indication of the lost revenue. This result provides valuable insight into whether it's worth addressing out-of-stock issues on the agenda (both internally and with trading partners).

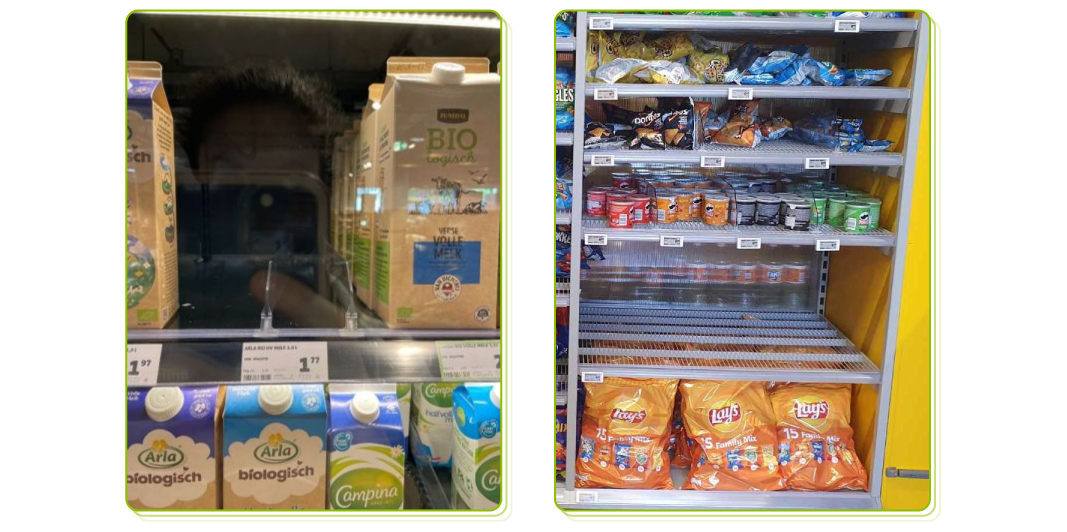

To get an idea of the "size of the price," SmartSpotter conducted a weekend out-of-stock measurement for a selection of seven products across five categories in nearly 100 Jumbo supermarkets in the second week of May.

Here are the results of the analyzed products (excluding promotional items):

The revenue loss quickly adds up to a considerable amount annually. Naturally, this is a snapshot, but this small sample could be a reason to prioritize addressing out-of-stock situations. In 1 out of 6 stores, Chips Party Mix is unavailable, and in 1 out of 8 stores, shoppers are left empty-handed in their search for Arla Halfvolle Milk.

For the two beer brands, we observe that the products are almost out-of-stock in 1 out of 5 stores and 1 out of 3 stores, respectively. The risk of out-of-stock, especially on weekends, is significant.

If you know the average sales per store, the percentage of weekend volume, and the shopper's response to out-of-stock, you can calculate the potential revenue loss. Based on a few good estimates, this could result in an annual "weekend" revenue loss of over $110,000 for Arla Halfvolle Milk 1L at Jumbo. Jumbo itself could experience an annual revenue loss of $50,000... all for one product!

Neglecting the issue of out-of-stock is a missed opportunity

In many cases, it can be quickly improved by focusing on the store floor. Once you've identified the cause and implemented a solution, you'll see results quickly. So don't ignore the out-of-stock problem... because your shoppers won't.

For this measurement, the following data was used: 50% rotation, 50% brand switch, and 20% store switch.